Scientists create film with cool benefits

Scientists have developed a material which is said to be capable of cooling objects even under direct sunlight.

Described as a metamaterial – a synthetic composite material with properties not usually found in nature – it has been developed by a team from the University of Colorado Boulder.

When applied to a surface, the metamaterial film cools the object underneath by reflecting the sun’s rays back into space while simultaneously allowing the surface to shed its own heat in the form of infrared thermal radiation.

The glass-polymer hybrid material is just 50 micrometers thick — slightly thicker than kitchen foil — and can be manufactured economically on rolls, making it a potentially viable large-scale technology for both residential and commercial applications.

The material takes advantage of passive radiative cooling, the process by which objects naturally shed heat in the form of infrared radiation, without consuming energy. To achieve this, researchers embedded visibly-scattering but infrared-radiant glass microspheres into a polymer film. They then added a thin silver coating underneath in order to achieve maximum spectral reflectance.

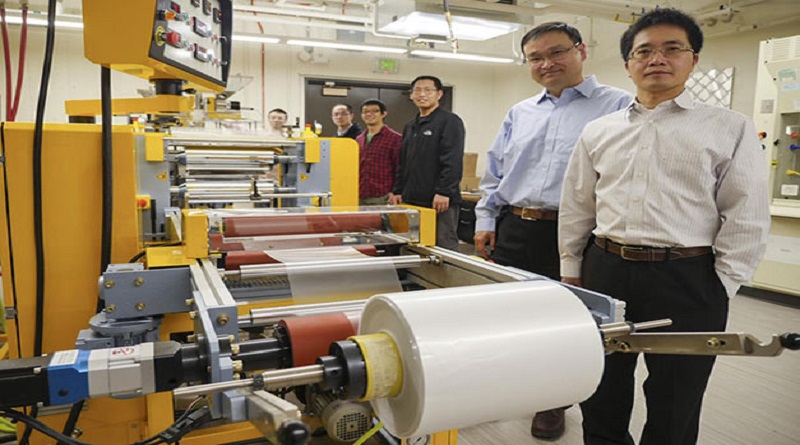

“Both the glass-polymer metamaterial formation and the silver coating are manufactured at scale on roll-to-roll processes,” explained Ronggui Yang, a professor of mechanical engineering and a Fellow of the American Society of Mechanical Engineers.

“Just 10 to 20 square metres of this material on the rooftop could nicely cool down a single-family house in summer,” said Gang Tan, an associate professor in the University of Wyoming’s Department of Civil and Architectural Engineering and a co-author of the paper, which is covered in the journal Science.

In addition to being useful for cooling of buildings and power plants, the material could also help improve the efficiency and lifetime of solar panels. In direct sunlight, panels can overheat to temperatures that hamper their ability to convert solar rays into electricity.

“Just by applying this material to the surface of a solar panel, we can cool the panel and recover an additional one to two percent of solar efficiency,” said Xiaobo Yin, co-director of the research. “That makes a big difference at scale.”

The engineers have applied for a patent for the technology and are working with CU Boulder’s Technology Transfer Office to explore potential commercial applications. They plan to create a 200m² “cooling farm” prototype in Boulder this year.

The invention is the result of a $3m grant awarded in 2015 by the US Energy Department’s Advanced Research Projects Agency-Energy (ARPA-E).

“The key advantage of this technology is that it works 24/7 with no electricity or water usage,” said Yang “We’re excited about the opportunity to explore potential uses in the power industry, aerospace, agriculture and more.”